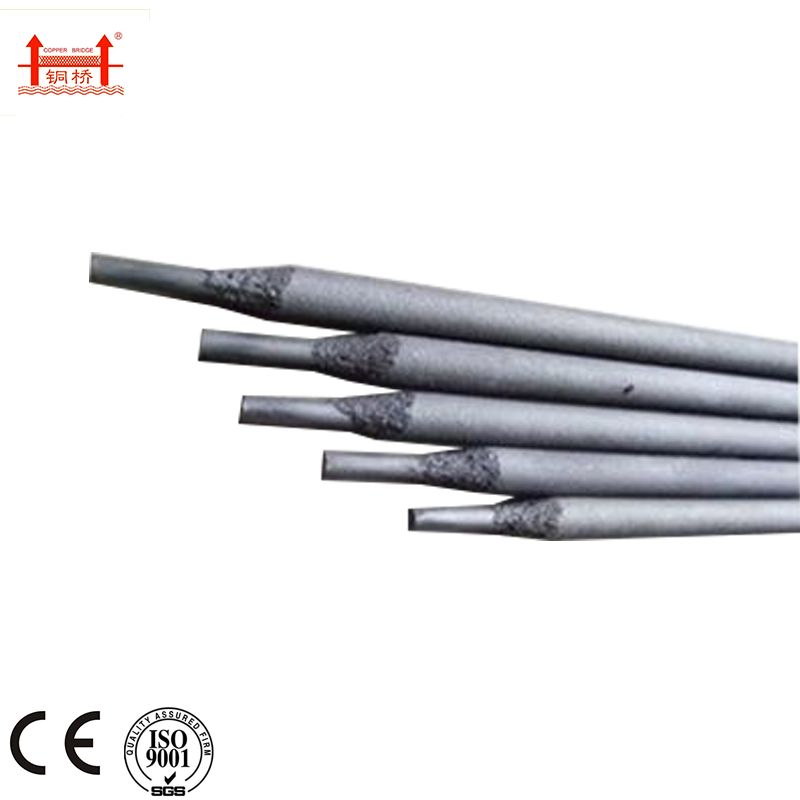

Stainless Simbi Electrodes CB-A102

Iyo Stainless simbi electrode kushandisa chiziviso

1. chromium Stainless steel ine imwe corrosion resistance (oxidizing acid, organic acid, cavitation) , kupisa kwekushisa uye kupfeka kusagadzikana.Inowanzo shandiswa mumagetsi zvidyarwa, makemikari, peturu uye zvimwe zvigadzirwa zvekushandisa.Chromium Stainless simbi yakashata weldability, inofanirwa kuterera kune welding process, kupisa kupisa mamiriro uye kusarudzwa kwakakodzera electrode.

2. CR-13 Stainless simbi ine yakakwirira kuomarara pashure welding uye zviri nyore kugadzira crack.Kana iyo yakafanana mhando yechromium Stainless simbi electrode (G202, G207) yakashandiswa pakunama, inofanira kunge yakagara ichipisa pamusoro pe300 ° C uye yakatonhodzwa inenge 700 ° C mushure mekugadzira.Kana iyo welding isingakwanisi kuitwa post-weld kupisa kurapwa, ipapo kusarudzwa kwechromium-nickel Stainless steel electrode (A107, A207) .

3. Chromium 17 simbi isina tsvina, kuitira kuti uvandudze kupikisa kwehutu uye weldability uye kuwedzera huwandu hwakakodzera hwezvinhu zvakagadzikana zvakadai seTi, Nb, Mo, nezvimwewo, weldability iri nani pane chromium 13 simbi isina tsvina.Kana mhando imwechete yechromium Stainless simbi electrode (G302, G307) ikashandiswa, inofanira kunge isati yatanga kupisa pamusoro pe200 ° C uye kudziya kutenderera 800 ° C mushure mekugadzira.Kana iyo welding isingagoni kupisa-kupisa, ipapo kusarudzwa kwechromium-nickel Stainless steel electrode (A107, A207).CR-NI Stainless simbi electrode ine yakanaka corrosion resistance uye oxidation kuramba, inoshandiswa zvakanyanya muindasitiri yemakemikari, fetereza, peturu, kugadzira michina yekurapa.

4. 0 uye pazasi inogona kushandiswa kune ese-nzvimbo welding.

5. 0 uye pamusoro kune flat welding uye fillet welding.

6. Chromium-nickel simbi isina tsvina ine titanium-calcium mhando uye yakaderera hydrogen mhando.Calcium titanate mhando inogona kushandiswa mu AC uye DC, asi kupinda kweakadzika AC welding, asi iri nyore kutsvuka, kuitira kushandisa DC magetsi.Diameter

7. Electrode inofanira kuchengetwa yakaoma, titanium-calcium type inofanira kuomeswa pa 150 ° C kweawa imwe, uye yakaderera hydrogen mhando inofanira kuomeswa pa 200 ° C kusvika 250 ° C kweawa 1 (hapana kuomeswa zvakare, kana zvisina kudaro. iyo yekuputira iri nyore kuputika uye kubvisa) , kudzivirira electrode coating sticking mafuta uye imwe tsvina, kuitira kuti isawedzera kabhoni yemukati we weld uye inokanganisa kunaka kwekutsvaira.

8. Kuti udzivise kuora pakati pemaziso kunokonzerwa nekupisa, iyo welding ikozvino haifaniri kunge yakakura, isingasviki carbon steel electrode inenge 20%, ARC haifaniri kunge yakareba, inokurumidza kutonhora pakati pezvikamu, kutetepa bead yakakodzera. .

| Model | GB | AWS | Dhayamita (mm) | Rudzi rweKupfeka | Current | Uses |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Lime-titania Type | DC | Inoshandiswa pakushongedza corrosion-resistant 0cR19Ni9 uye 0Cr19Ni11Ti Stainless simbi zvivakwa zviri pasi pe300︒C |

Kemikari Inoumbwa yeDeposited Metal

| Kemikari Inoumbwa yeDeposited Metal (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Mechanical Properties yeDeposited Metal

| Mechanical Properties yeDeposited Metal | |

| Rm(Mpa) | A(%) |

| ≥550 | ≥35 |

Packing

Factory Yedu

Exhibition

Yedu Certification